-3.png)

Wood Plastic Composite (WPC) products have emerged as a revolutionary solution in the construction and outdoor living industry, blending the best characteristics of wood and plastic to create a versatile and sustainable material. The background of WPC products is a fascinating journey that combines innovation, environmental consciousness, and the quest for durable, low-maintenance alternatives to traditional materials.

The roots of WPC products trace back to the early 1990s when engineers and researchers sought ways to address the limitations of pure wood and plastic materials. The desire was to create a composite material that would inherit the appealing aesthetics of wood while overcoming its susceptibility to decay, rot, and pests. Simultaneously, the goal was to harness the durability and weather resistance of plastics, mitigating issues like warping and cracking.

transform high standards

productivate next-generation

The breakthrough came with the successful combination of wood fibers or flour with thermoplastic resins, often derived from recycled materials. The resulting WPC material offered a unique synergy, marrying the natural look and feel of wood with the durability, water resistance, and low maintenance of plastic.

One of the primary advantages of WPC products lies in their environmental friendliness. By incorporating recycled materials, WPC contributes to reducing the demand for virgin plastics and lessening the environmental impact of wood extraction. This eco-friendly aspect aligns with the growing global awareness of sustainable practices and responsible sourcing.

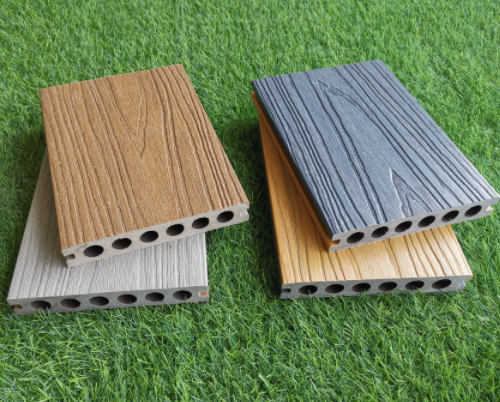

WPC products quickly found applications in various industries, with decking being one of the most prominent. WPC decking became a popular choice for outdoor spaces, providing a long-lasting, splinter-free, and aesthetically pleasing alternative to traditional wooden decks. Beyond decking, WPC has been employed in fencing, cladding, furniture, and even in the automotive industry for interior components.

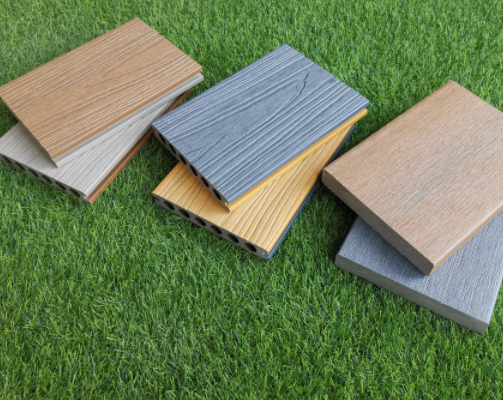

The manufacturing process of WPC involves mixing wood fibers or flour with thermoplastic resins under controlled conditions. The resulting mixture is then extruded or molded into the desired shape. The ability to customize WPC products in terms of color, texture, and size has further fueled its widespread adoption.

As the market for WPC products continues to grow, ongoing research and development are focused on enhancing the material’s performance, expanding its applications, and exploring new sustainable additives. The background of WPC products reflects not only a technical innovation but also a commitment to sustainability, meeting the demands of a world increasingly conscious of the environmental impact of materials used in construction and everyday life.