Wood-Plastic Composites (WPCs) can be enhanced with various additives to improve their performance and appearance. Some of the most common additives used in WPC production include water repellents, UV repellents, pigments, and coloring agents.

Water repellents are additives that help protect WPCs from moisture absorption, which can lead to swelling, warping, and decay. These additives are particularly important for outdoor applications where the material is exposed to rain and humidity.

transform high standards

productivate next-generation

UV repellents are additives that help protect WPCs from the damaging effects of ultraviolet (UV) radiation, which can cause fading, discoloration, and degradation of the material. These additives are essential for maintaining the appearance and longevity of WPCs exposed to sunlight.

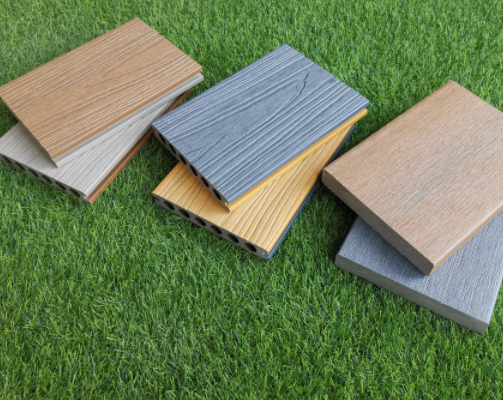

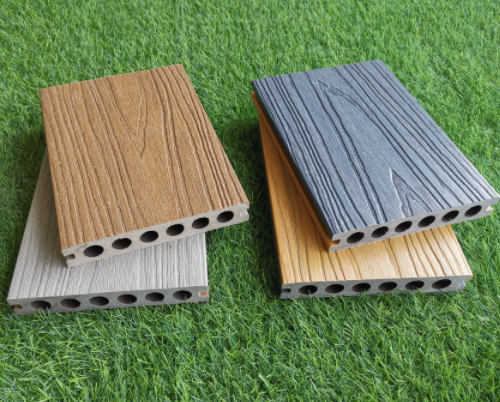

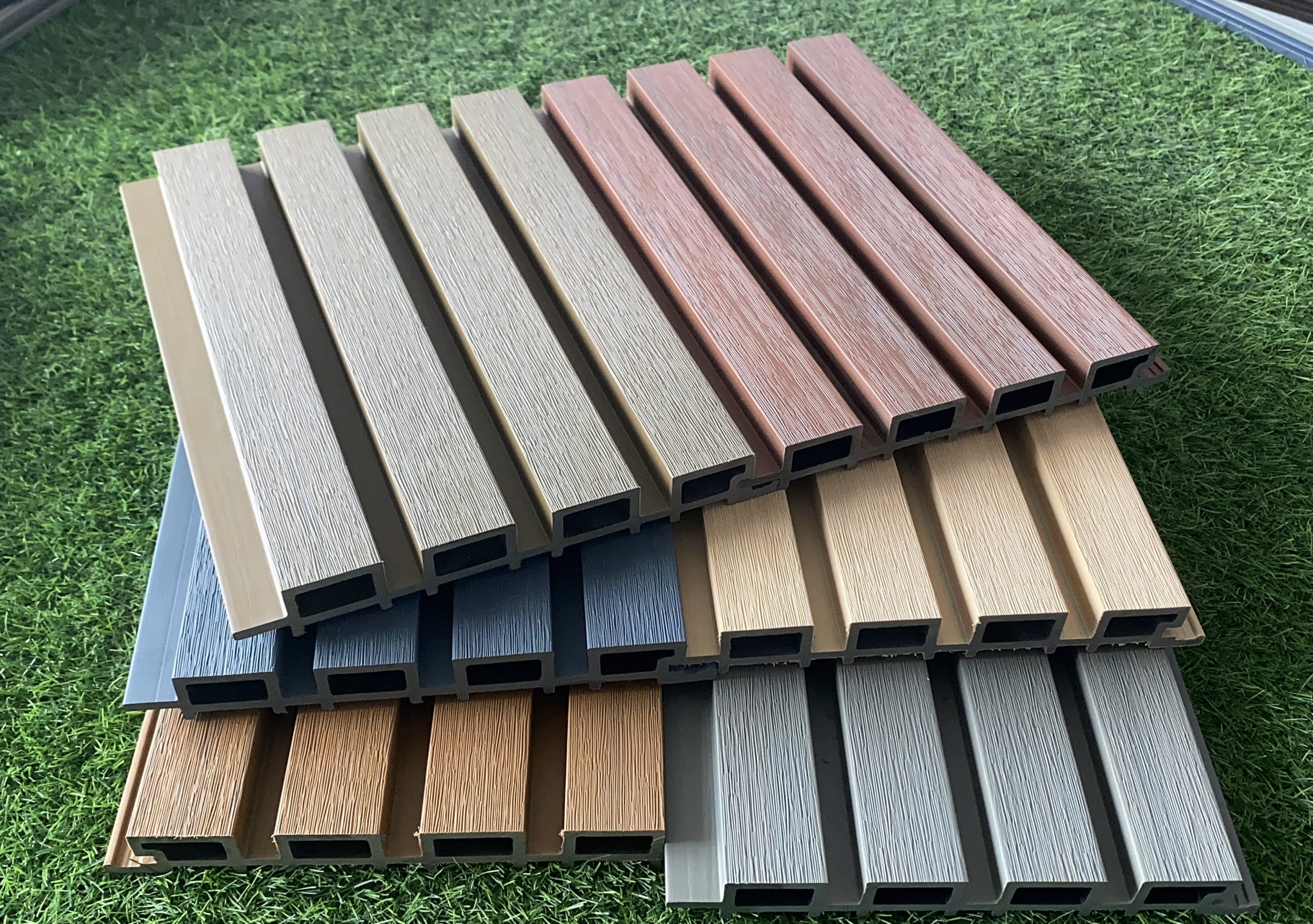

Pigments and coloring agents are additives used to add color to WPCs, enhancing their aesthetic appeal and allowing for customization to suit different design preferences. These additives are available in a wide range of colors and can be used to achieve various effects, from natural wood tones to vibrant shades.

In conclusion, additives play a crucial role in enhancing the performance and appearance of Wood-Plastic Composites (WPCs), allowing for greater durability, weather resistance, and aesthetic flexibility.