Integrity – Focus – Quality

achieve your goals with purpose & strategy

We have our own wood powder factory, and from raw materials to finished products, there is a professional quality inspection department that provides full-course tracking.

Integrity – Focus – Quality

WPC production process

Granulation – Extrusion – Surface treatment – Packaging.

The first step in the production process of WPC flooring is mixing.

In the mixing stage, we blend PE, wood powder, and other additives together in predetermined proportions according to the formula. This step ensures the uniform distribution of raw materials and lays a solid foundation for subsequent production processes.

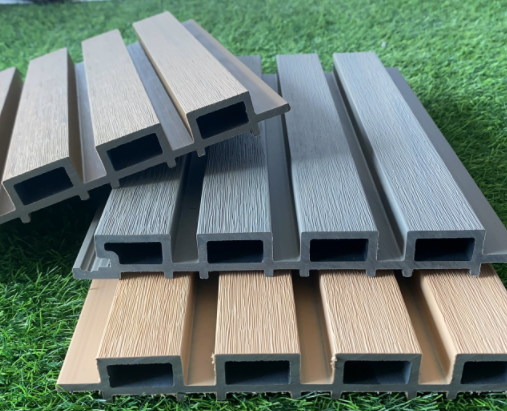

The second step in the production process of WPC flooring is extrusion.

The mixed raw materials are fed into the extruder, where they are melted into a uniform molten state under high temperature and pressure. The molten material is then extruded through the die opening to form the base material for WPC flooring.

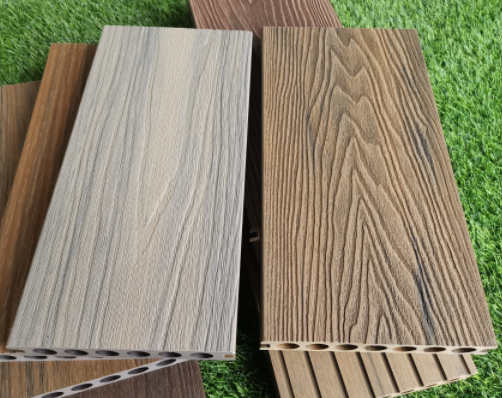

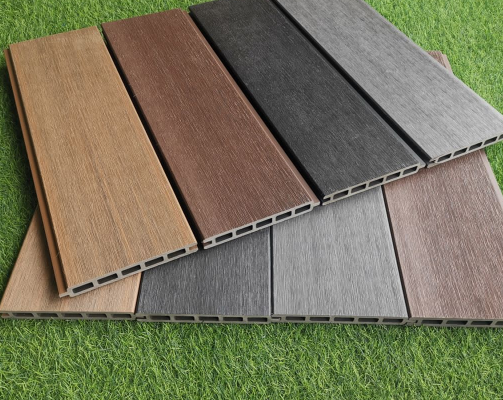

The third step in the production process of WPC flooring is surface treatment.

In the surface treatment stage, we place the extruded profiles into specific machines for sanding and polishing to enhance their surface finish and texture. This step smoothens and beautifies the surface of the WPC flooring, increasing the added value of the product.

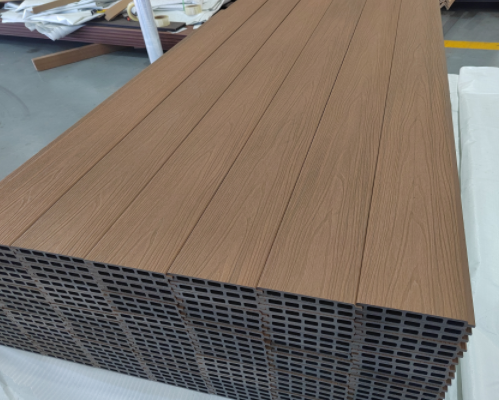

The fourth step in the production process of WPC flooring is packaging.

After completing the surface treatment, the WPC flooring is packaged for shipment. We use professional packaging materials and equipment to ensure that the products are not damaged during transportation and maintain their integrity.

Projects we have completed previously